ATLAS METAL WORKS, LLC

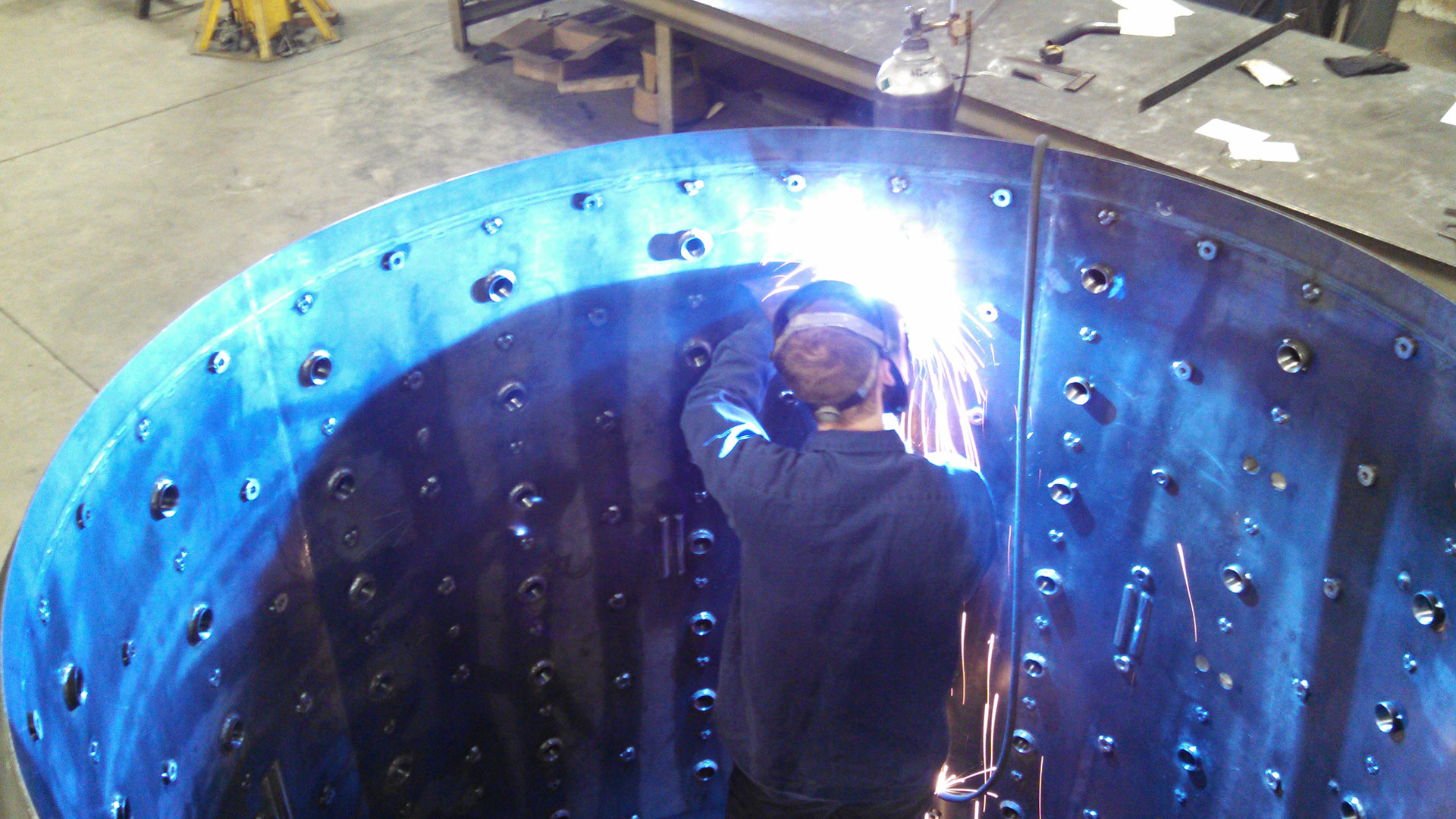

Atlas Metal Works, LLC is a custom metal fabrication house serving the commercial market including general contractors, construction companies, O.E.M. manufacturers, and other large and small businesses. In addition, we service fabrication houses and manufacturers who do not have the capability. We handle shearing, bending, burning, laser cutting, welding, and hole punching from gauge metal to heavy plate. We sell raw materials: sheets, plates, angles, flats, channels, full length, full sheets, or cut to size. We do complete projects, large or small, from design to finished product using all design files. You can email us your AutoCAD, FastCAM, or FastSHAPES design file; or we can create your design for you. Either way, we can generate your parts accurately and still meet timely delivery dates.